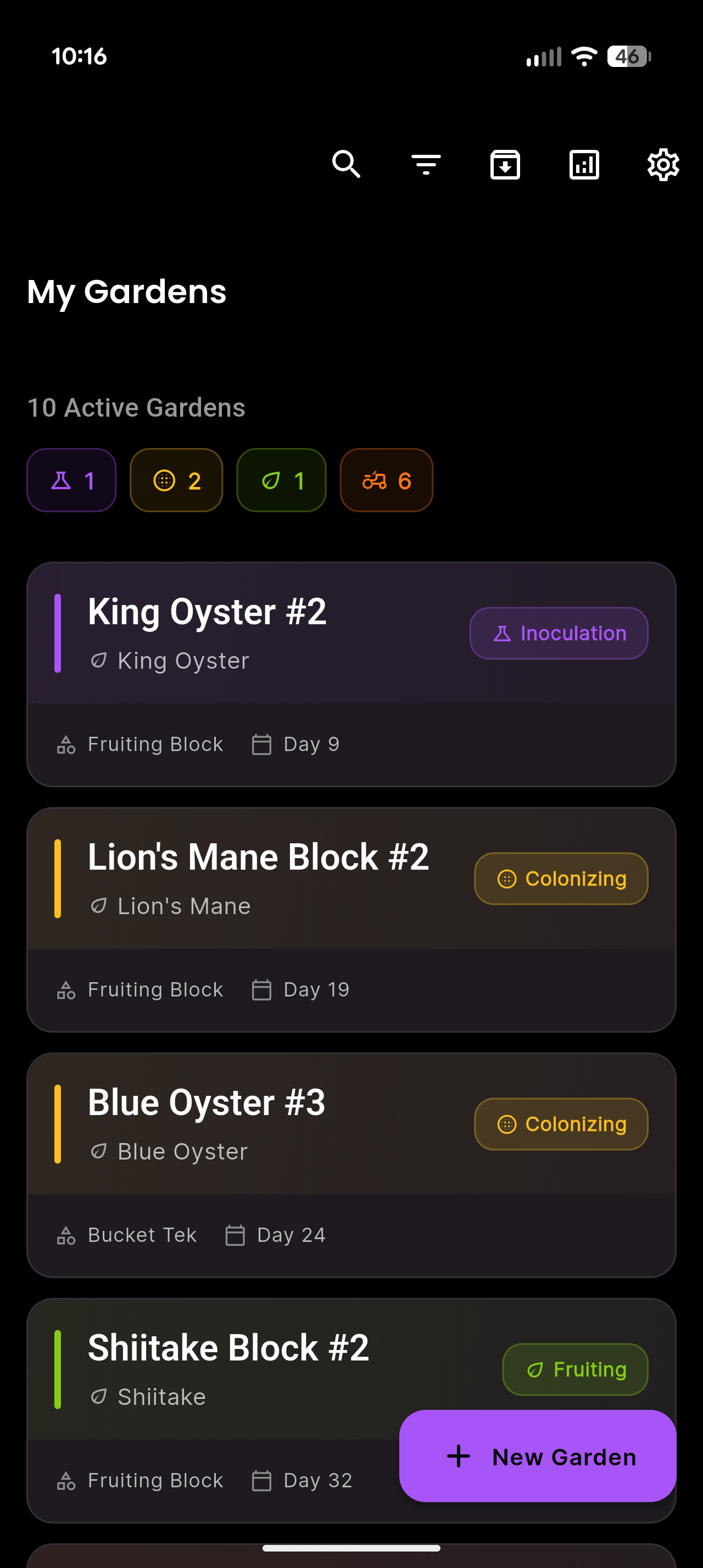

Dashboard featuring real-time sensor readings, environmental thresholds, substrate batch status, and harvest tracking.

PLACEHOLDER: Sensor pairing screen showing BLE and WiFi device discovery

Sensor pairing with automatic BLE and WiFi device discovery.

PLACEHOLDER: Substrate batch detail view with QR code and growth stage timeline

Substrate batch detail with QR tracking and growth stage timeline.

Real-Time Monitoring

24/7 sensor data with threshold alerts for temperature, humidity, and CO2 across every growth stage.

Substrate Management

QR-based tracking from inoculation through harvest, with batch histories and yield analytics.

Smart Alerts

Push notifications for out-of-range conditions, ensuring immediate response to environmental drift.

PLACEHOLDER: Environmental dashboard with live temperature, humidity, and CO2 gauges

Live environmental dashboard with real-time gauges for temperature, humidity, and CO2 levels.

PLACEHOLDER: Time-series chart showing temperature and humidity trends over 7 days

Time-series charts with configurable date ranges and threshold overlays.

PLACEHOLDER: Alert history screen showing notification log with severity levels

Alert history with severity levels and environmental condition snapshots.

PLACEHOLDER: Harvest log screen with yield weights and batch associations

Harvest logging with yield tracking.

PLACEHOLDER: Sensor management screen showing connected devices and battery levels

Sensor management and device health.

PLACEHOLDER: Growth stage configuration with environmental parameter ranges

Growth stage configuration and thresholds.

IoT Sensor Ecosystem

MycoLog supports multiple connectivity protocols, enabling flexible sensor placement across growing environments with reliable data capture.

Bluetooth (BLE)

Short-range, low-power sensors

WiFi

Long-range, always-connected

Hybrid

BLE + WiFi bridge devices

PLACEHOLDER: QR code scanning screen for substrate batch identification

QR scanning for substrate batch tracking.

PLACEHOLDER: Batch analytics showing inoculation-to-harvest timeline with environmental correlation

Batch analytics and cultivation timeline.

PLACEHOLDER: Settings screen with notification preferences and sensor calibration options

Settings and sensor calibration.

The Process

Mushroom cultivation demands environmental precision that most hobbyists track manually or not at all. Temperature, humidity, and CO2 levels must stay within narrow ranges that shift across growth stages -- colonization, pinning, fruiting -- and even small deviations can stall growth or invite contamination. I built MycoLog to replace guesswork with continuous, automated monitoring that adapts to each stage's requirements.

The IoT sensor layer was the core technical challenge. I prototyped across three connectivity approaches -- Bluetooth Low Energy for short-range low-power sensors, WiFi for always-connected devices, and hybrid BLE-to-WiFi bridges for flexible placement. Browser API compatibility varied significantly across Android and iOS, requiring platform-specific workarounds for BLE pairing flows. After extensive calibration testing, the sensor pipeline achieved 99.2% data accuracy with sub-second latency on local reads.

Data visualization drove the UX design: time-series charts with threshold overlays let growers spot environmental drift at a glance, while QR-based substrate batch tracking ties environmental conditions back to specific inoculation-to-harvest cycles. The app is currently in closed testing with 2 active users, iterating on alert tuning and sensor reliability across multi-room setups before expanding the testing group. Validating that the interaction language translates across domains--from filament tracking to environmental monitoring--shaped our sensor integration approach.

PLACEHOLDER: IoT sensor integration architecture showing BLE, WiFi, and hybrid connectivity

IoT sensor integration architecture

PLACEHOLDER: Growth stage environmental parameter ranges chart

Growth stage environmental parameters

PLACEHOLDER: Time-series sensor data visualization with threshold alerts

Time-series sensor data visualization

Impact

In Closed Testing

IoT Device Types

Sensor Data Accuracy