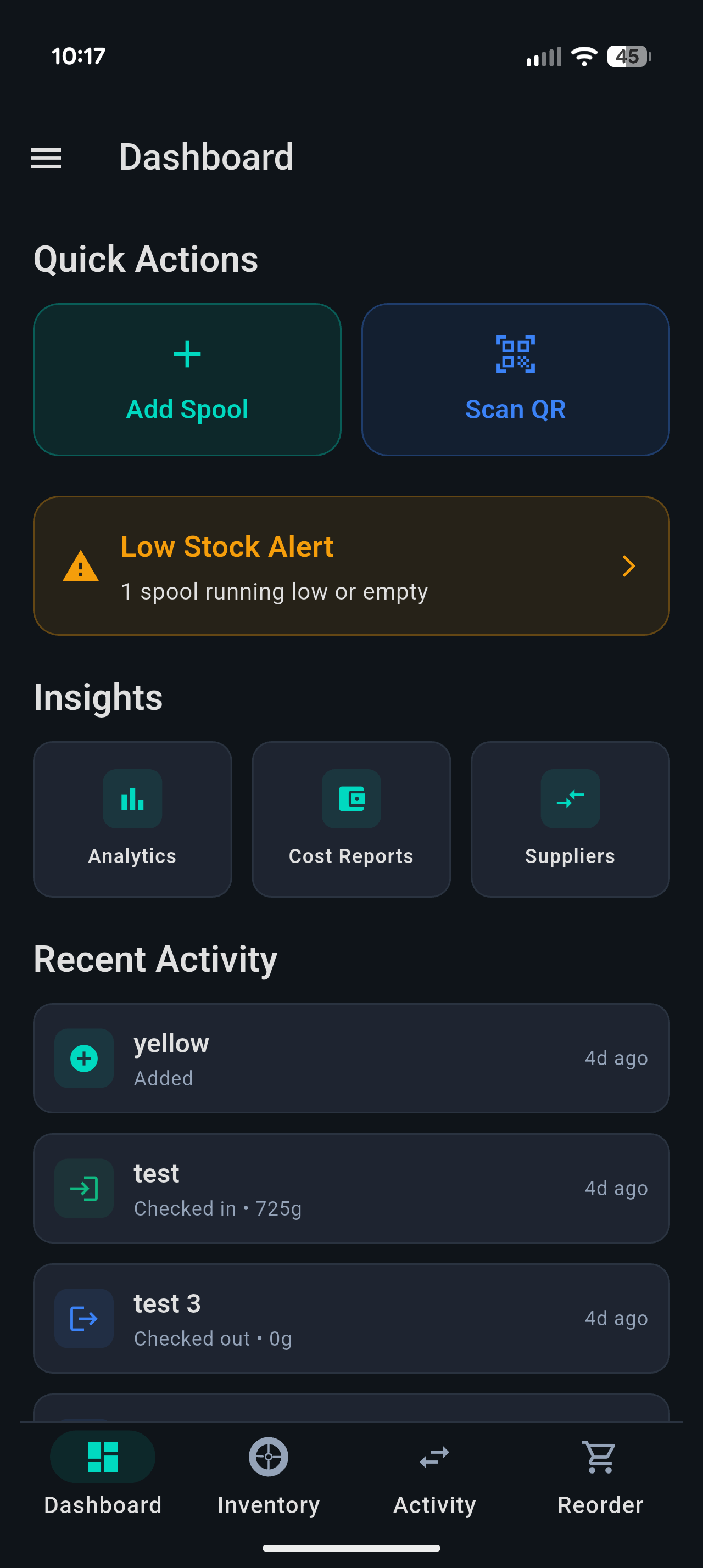

Dashboard featuring Quick Actions, low stock alerts, analytics insights, and recent activity tracking.

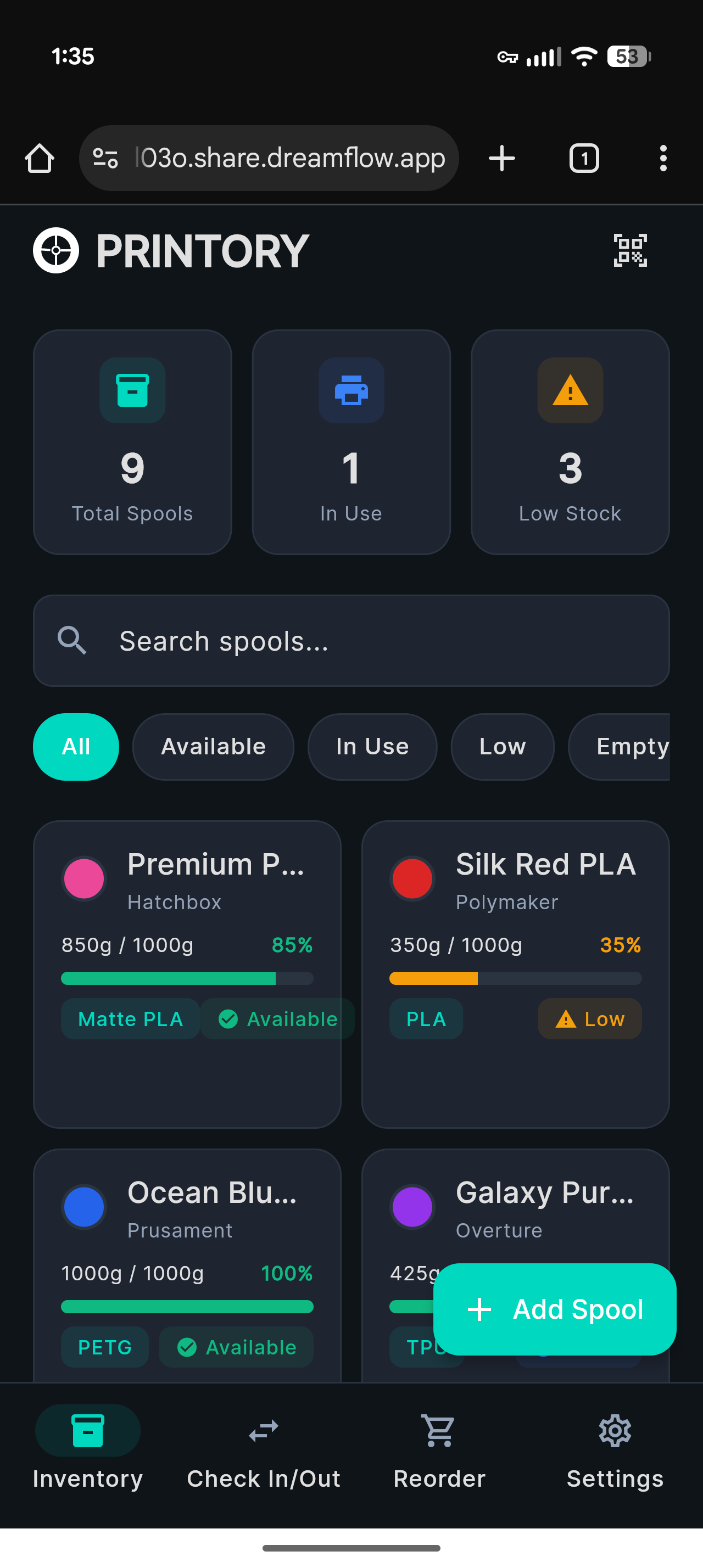

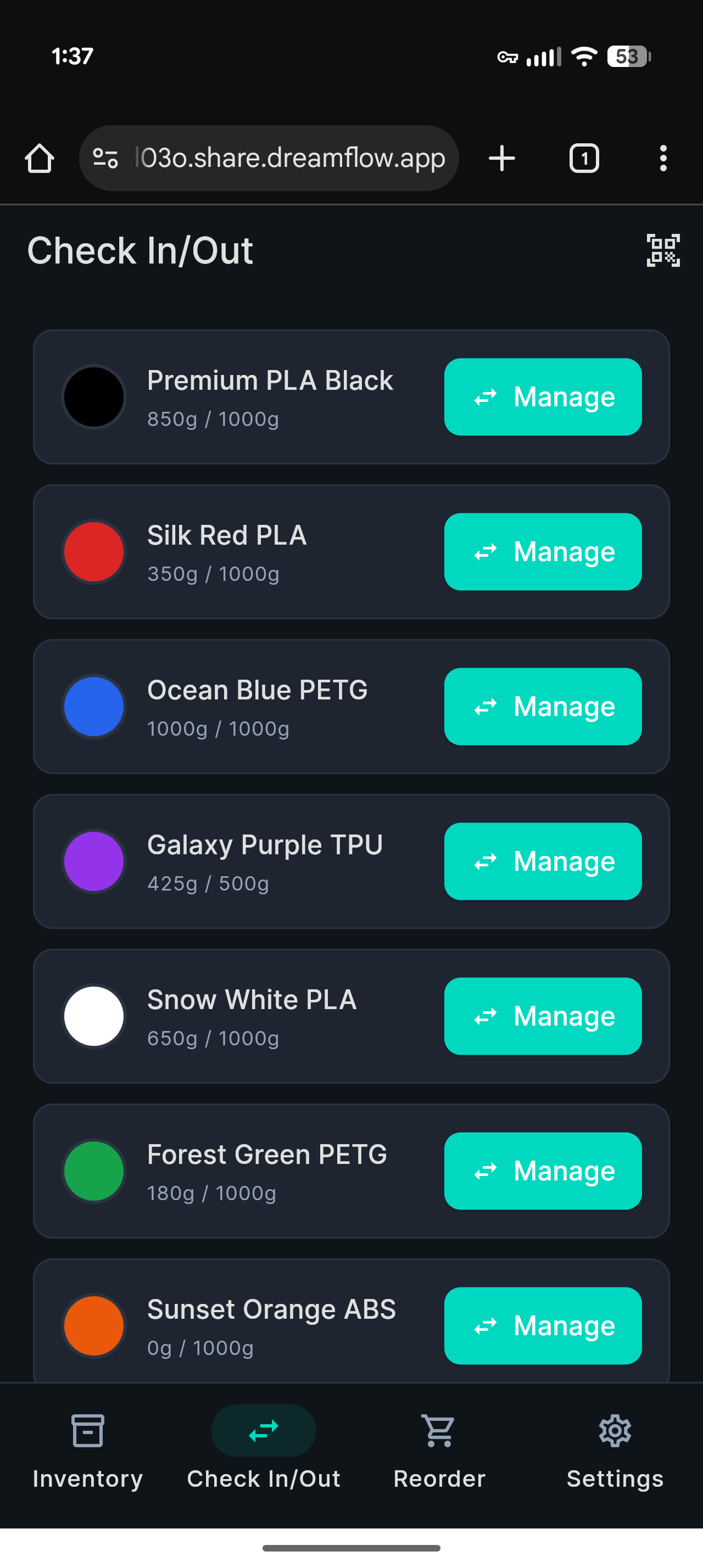

Inventory view with color swatches, material types, and stock percentages.

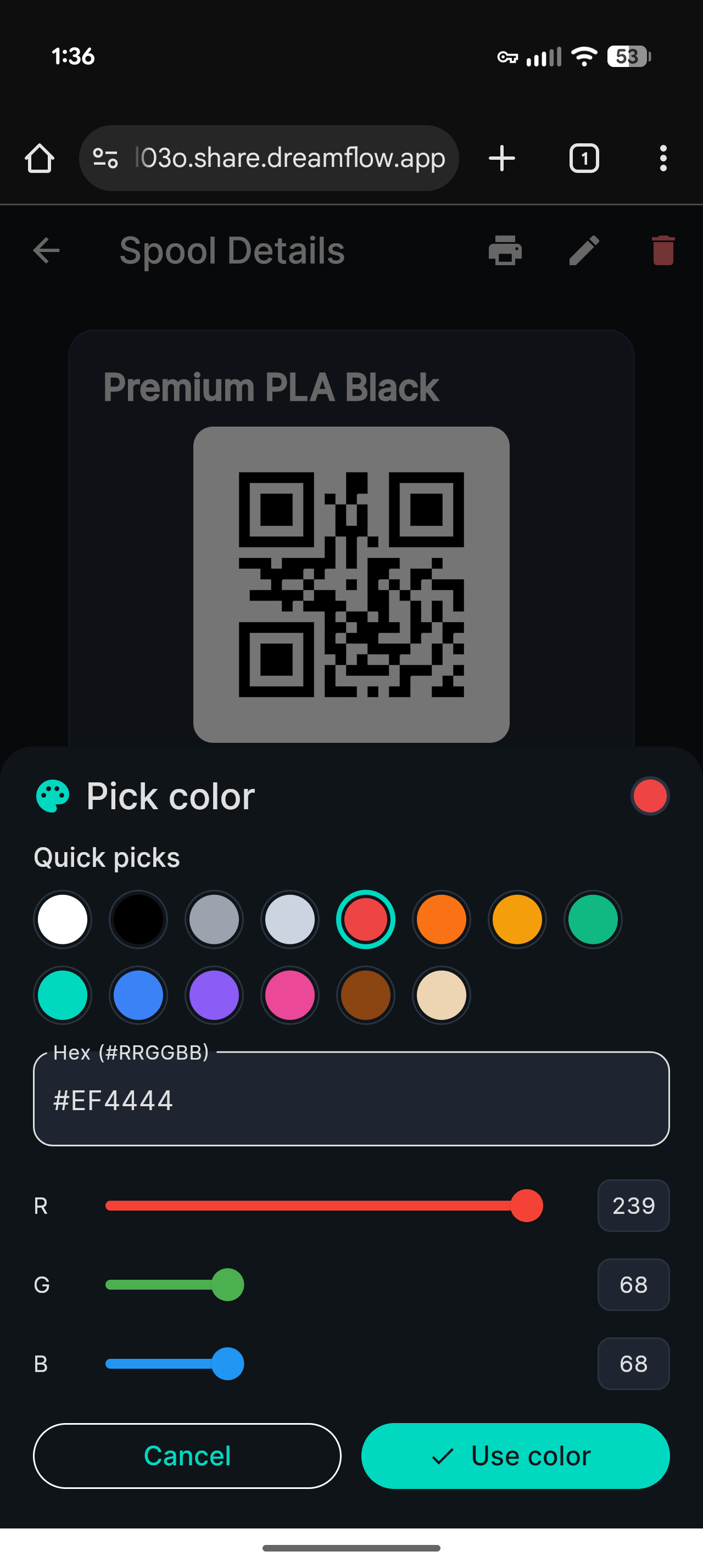

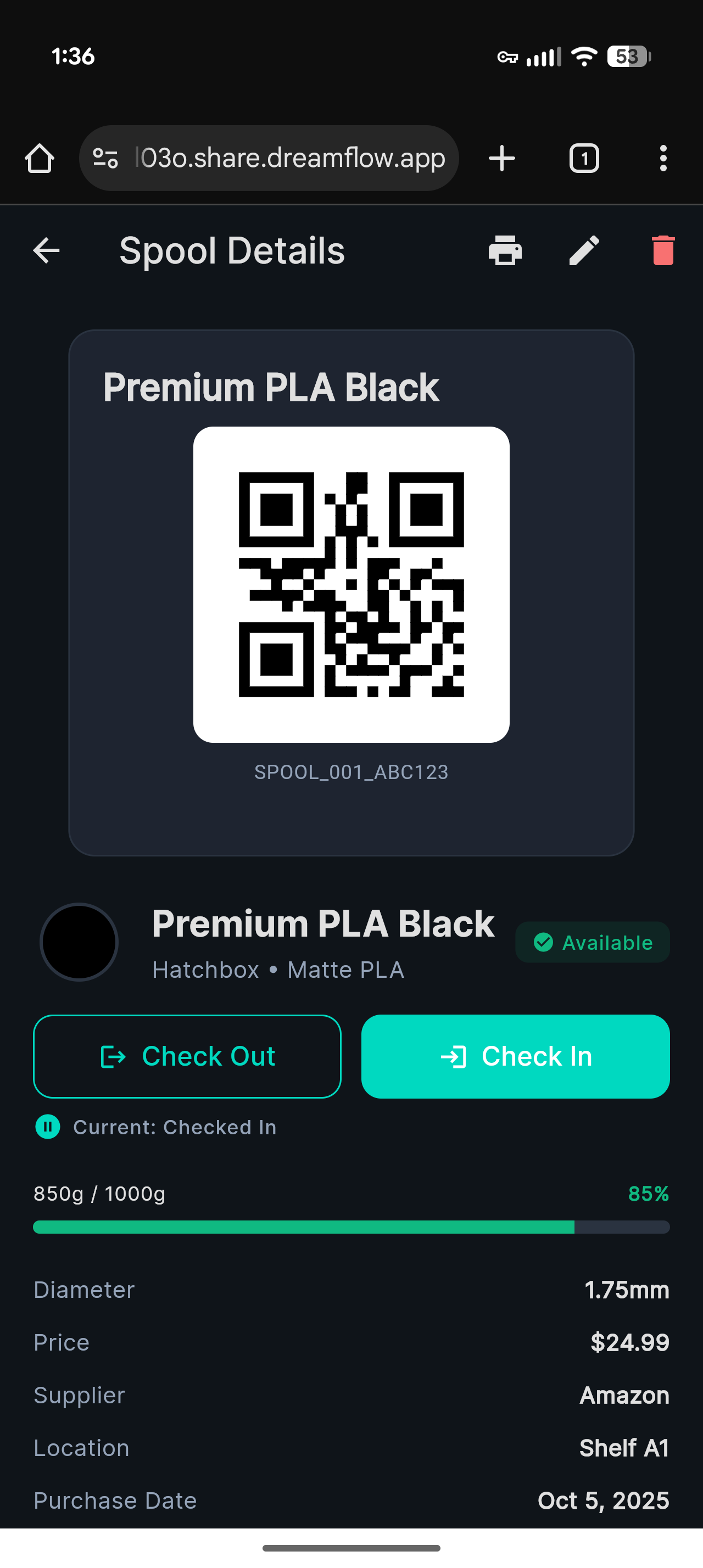

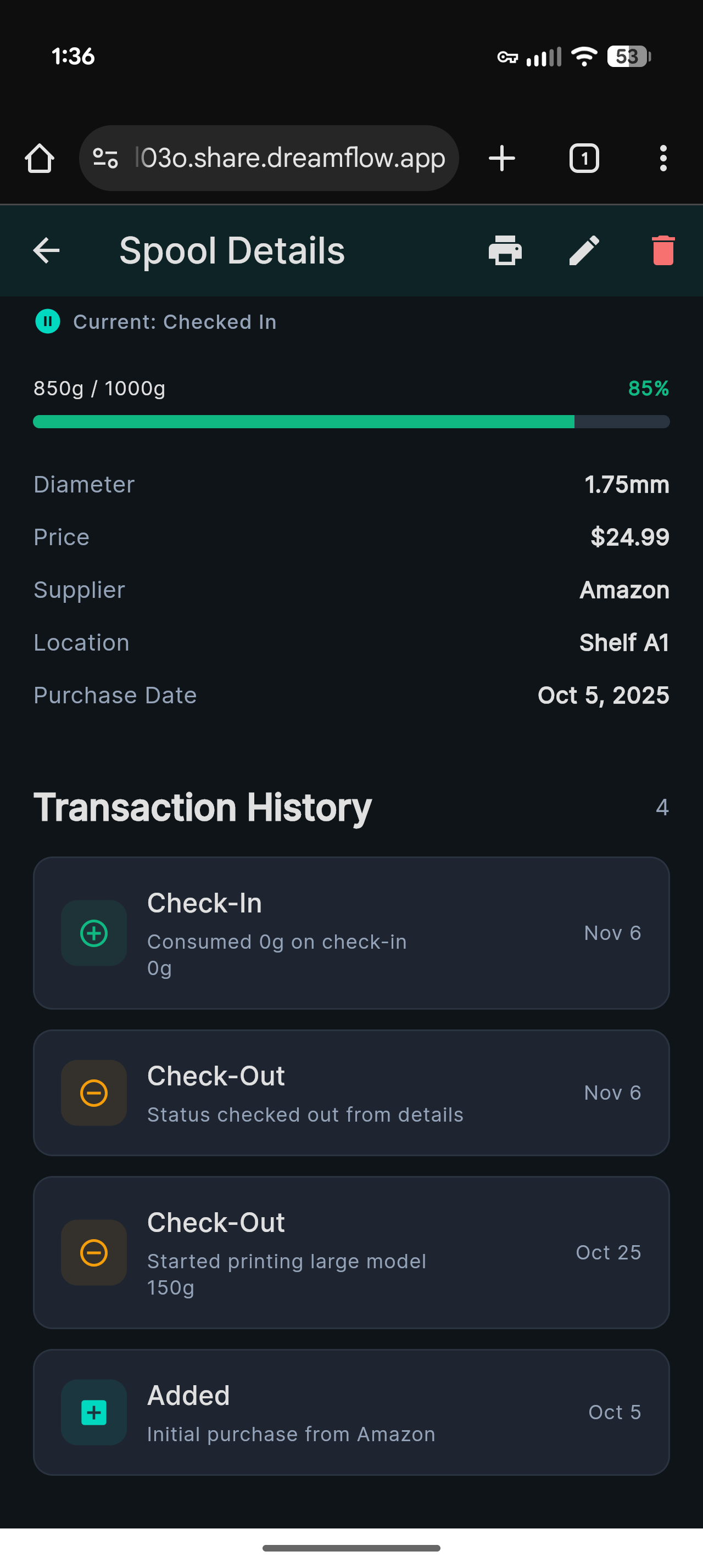

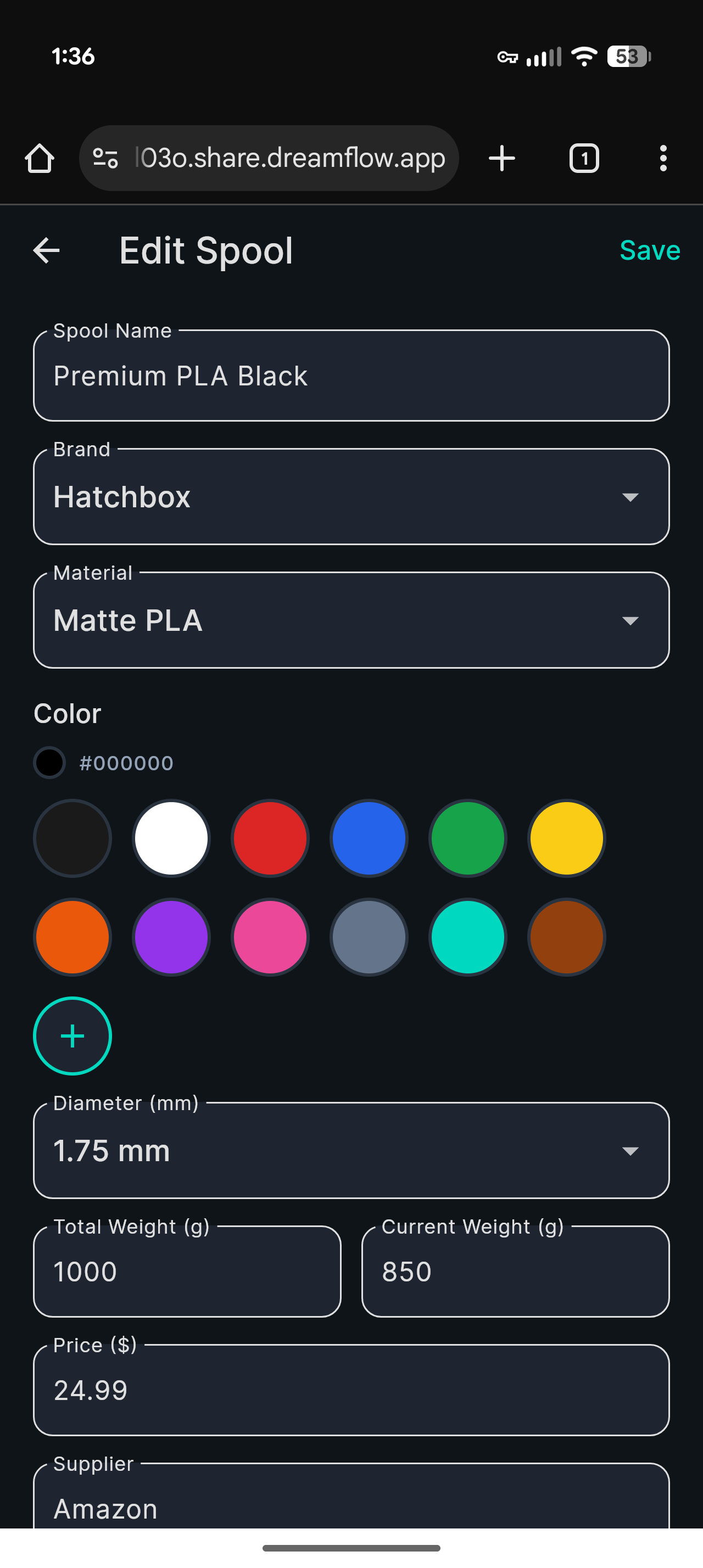

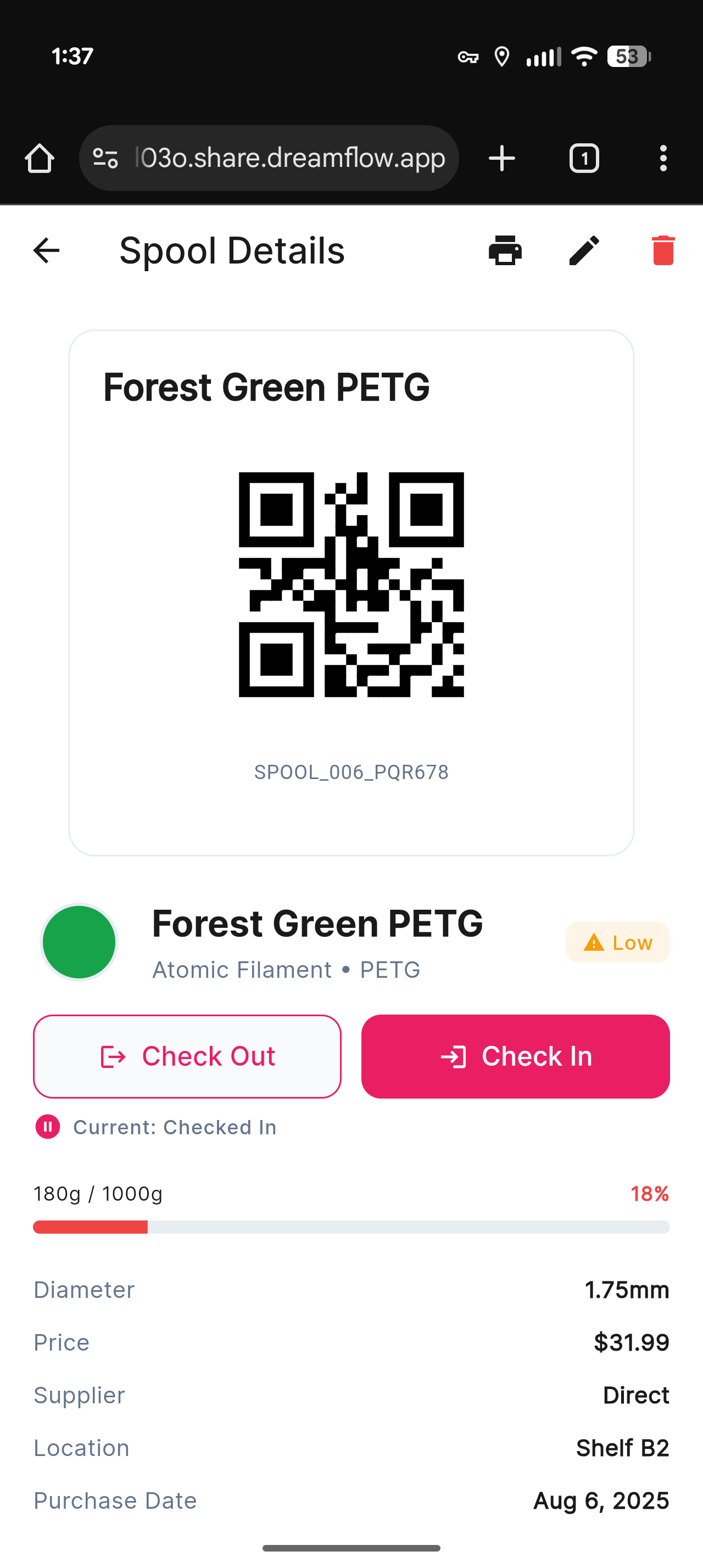

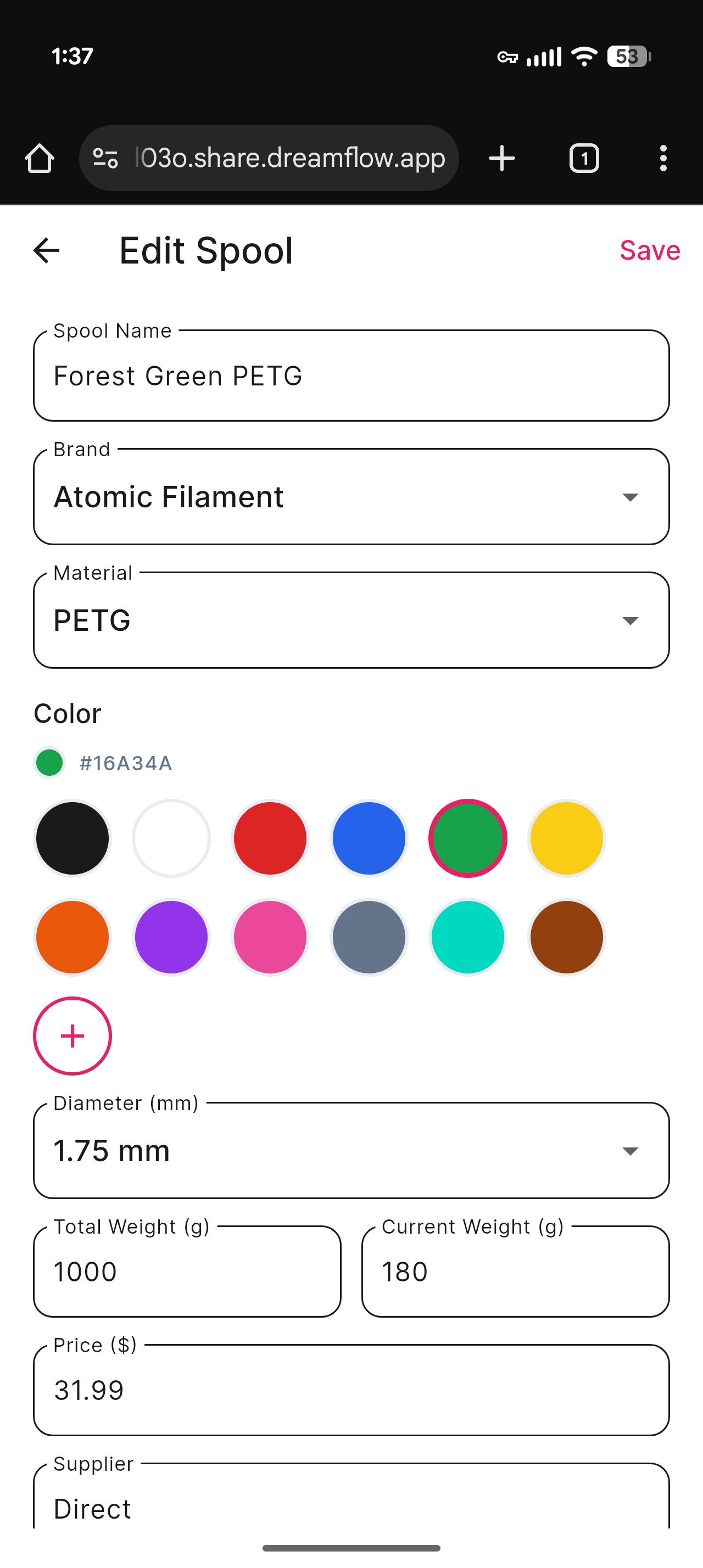

Spool details: QR code, color picker with RGB controls, and material ID.

QR Code Scanning

Scan spools instantly with 98% success rate across lighting conditions and angles.

Spool Inventory

Track materials, colors, stock levels, and usage across your entire filament collection.

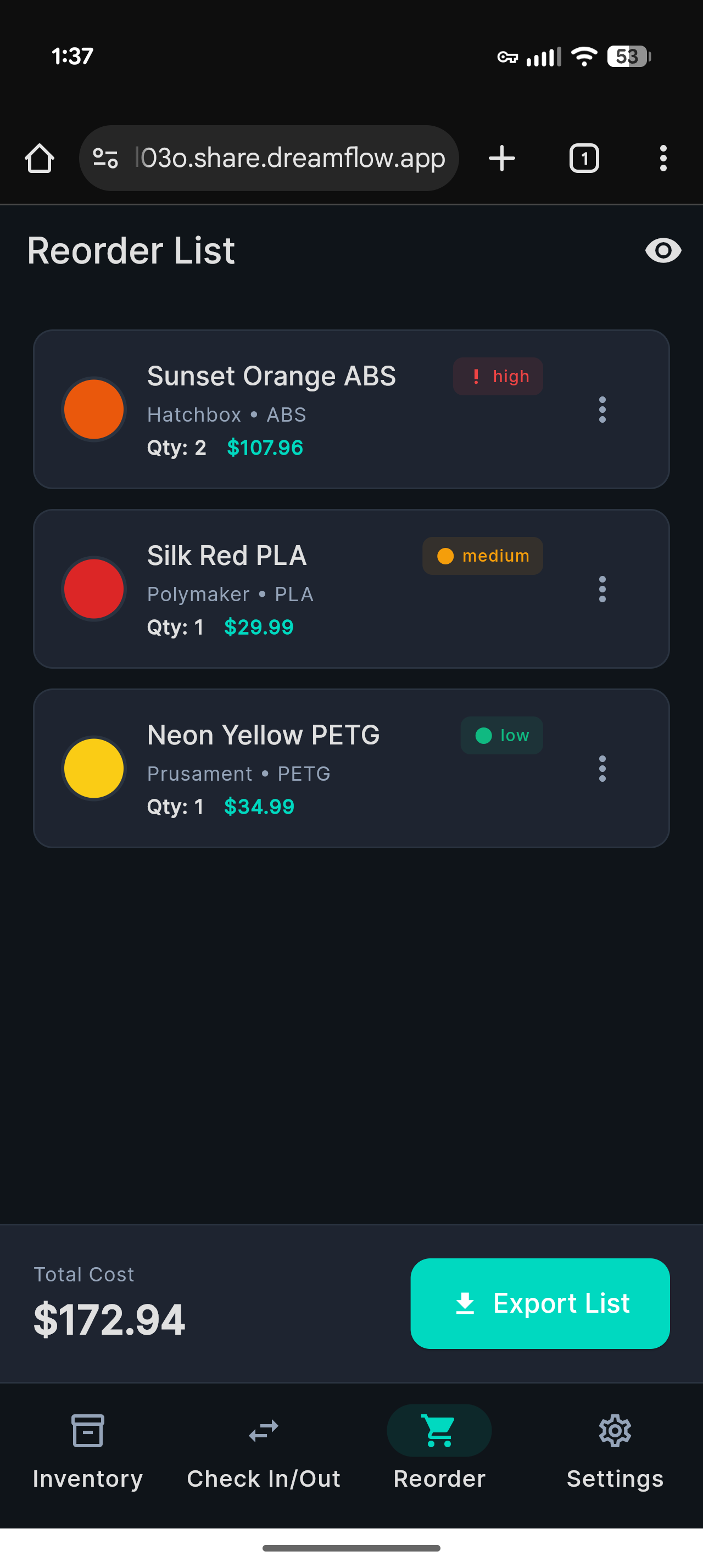

Low Stock Alerts

Automatic notifications when filament runs low, preventing mid-print failures.

Each spool generates a unique QR code — scan to identify, check in, or log usage.

Quick check-in with preset amounts (0g, 10g, 25g, 50g, 100g) for frictionless logging.

Usage history and analytics for tracking consumption over time.

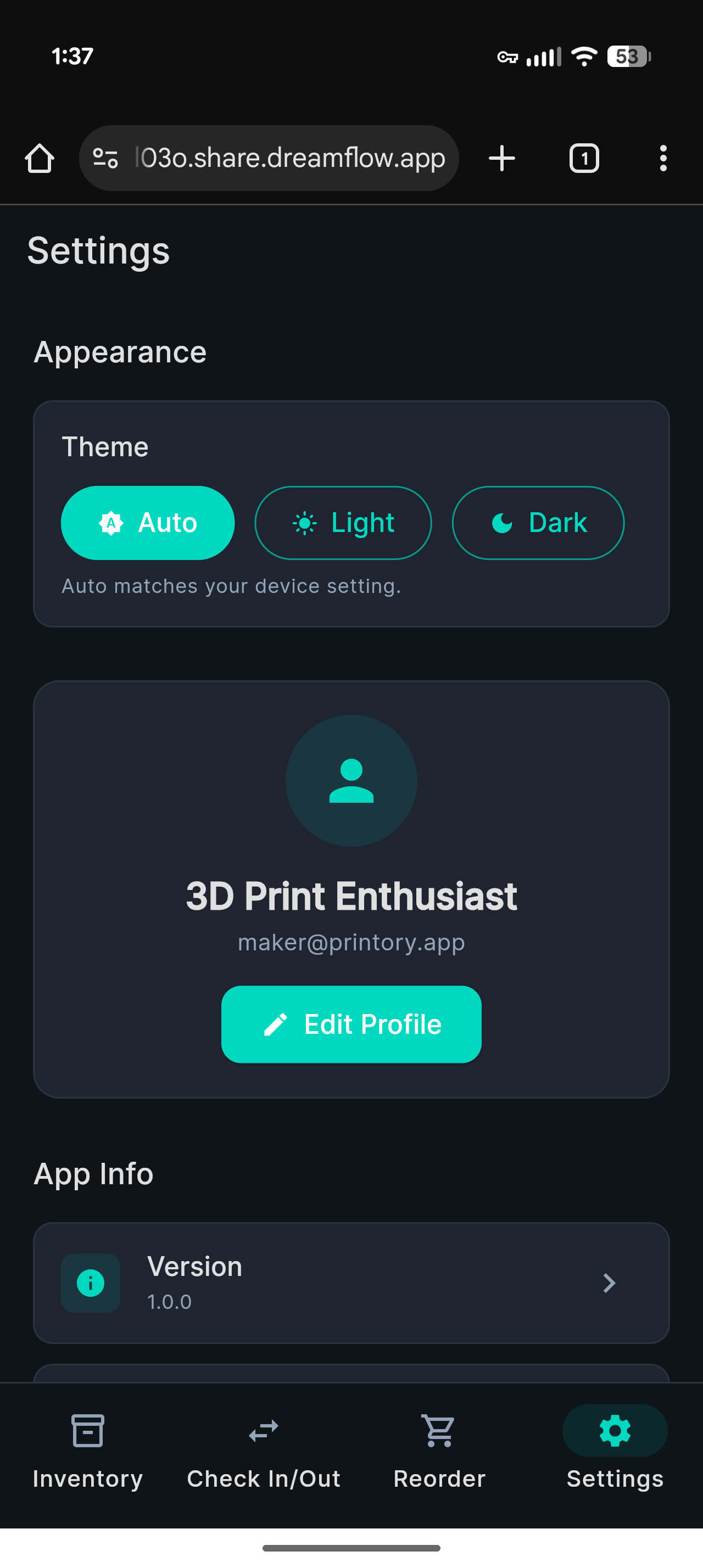

Settings and configuration.

Material type library and management.

Add new spools with material and color details.

Reusable Architecture

Printory's component architecture became the foundation for two additional apps, proving the value of designing for reusability from day one.

Printory

Core architecture — 2 months

HydroMate

Adapted in 3 days

Verdant Lab

Adapted in 3 days

Detailed spool view with complete information.

Color management and visual organization.

Analytics and inventory overview.

The Process

As a 3D printing hobbyist, I understood the inventory chaos firsthand — dozens of filament spools across different materials, colors, and brands tracked in spreadsheets that quickly became outdated. The pain point was acute: starting a print only to discover an empty spool, or wasting time searching bins for the right color. I built Printory to solve this with a frictionless mobile workflow: scan a QR code, see inventory status, done.

The architecture prioritized reusability from day one. I abstracted core patterns — data models, UI components, state management — anticipating that inventory tracking logic could adapt to other domains. Real-device testing revealed insights desktop prototypes could never capture: camera permissions, scanning angles, lighting conditions, and latency. I iterated rapidly on the scanning experience, optimizing QR detection and adding visual feedback, pushing success rate to 98%. Testing whether QR code interaction felt natural through rapid prototyping revealed critical insights about camera workflow expectations.

After two months of iteration, Printory entered closed testing on Google Play with 12 active users. More importantly, the reusable component architecture became the foundation for HydroMate and Verdant Lab — both adapted in just 3 days — validating that investing in reusable patterns from day one compounds returns across future products.

PLACEHOLDER: Component architecture diagram showing shared modules across Printory, HydroMate, and Verdant Lab

Reusable component architecture

PLACEHOLDER: QR scanning workflow diagram showing scan → identify → check-in flow

QR scanning workflow

PLACEHOLDER: Data model diagram showing spool, material, and usage tracking relationships

Inventory data model

Impact

To Closed Testing

On Google Play

QR Scan Success Rate